Ultra-Ever Dry

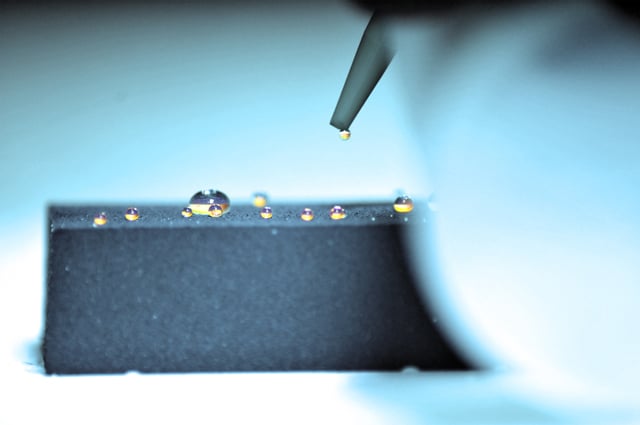

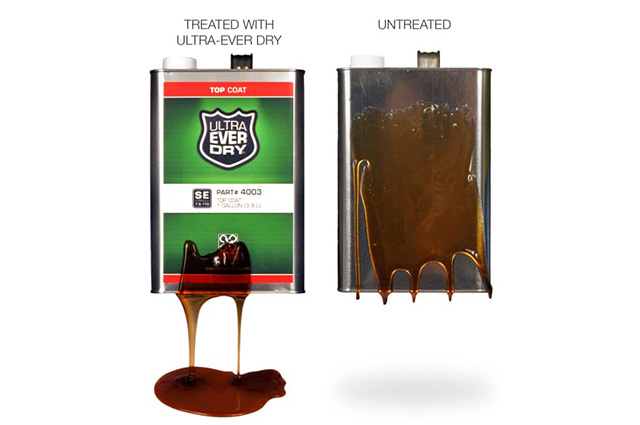

Ultra-Ever Dry is a superhydrophobic (water) and oleophobic (hydrocarbons) coating that will completely repel almost any liquid

HOTLINE: 800.764.9566 • 904.854.4334

FOR INDUSTRIAL USE ONLY. NOT AVAILABLE TO CONSUMERS AT THIS TIME.

Ultra-Ever Dry does NOT dry clear! It cannot be used on automobile windshields and obscures visibility through glass. Click here for information on a coating that is clear and more durable.

Ultra-Ever Dry is a superhydrophobic (water) and oleophobic (hydrocarbons) coating that will repel most water-based and some oil-based liquids. Ultra-Ever Dry uses proprietary omniphobic technology to coat an object and create a surface chemistry and texture with patterns of geometric shapes that have “peaks” or “high points”. These high points repel water, some oils, wet concrete, and other liquids unlike any other coating.

Ultra-Ever Dry has vastly improved adhesion and abrasion resistance, compared to previous superhydrophobic technologies, allowing it to be used in applications where greater durability is required.

Product Highlights:

Anti-Wetting

The superhydrophobic coating keeps objects dry. Water and many other liquids are easily repelled.

Anti-Corrosion

Ultra-Ever Dry offers enhanced corrosion protection since the superhydrophobic coating repels water, saltwater, aqueous acids, and bases.

Anti-Icing

The superhydrophobic properties of Ultra-Ever Dry keep coated materials completely dry, eliminating the formation of ice or, in the case of frost, making the removal of ice dramatically easier.

Anti-Contamination

Water and other liquids that contain bacteria or radiation never actually contact the surface of the coated material so bacteria and radiation are greatly diminished or eliminated and the surface is easy to decontaminate. Dust and dirt are easily removed with low-pressure water.

Self-Cleaning

Ultra-Ever Dry repels dirty water and some oils, and remains clean and virtually bacteria-free. When dust, dirt or other molecules accumulate on a superhydrophobic coated surface, a light spray of water or a blast of air grabs the dust and removes it.

Product Life-Extending

Many products fail from moisture, water, oil or simply getting too dirty for continued use. Use Ultra-Ever Dry superhydrophobic coating to extend the life of electric motors by preventing the build-up of moisture on the windings, coat nuts, and bolts to prevent corrosion, coat tools, equipment, and virtually any item that needs to be kept dry, corrosion free, de-iced, uncontaminated or clean. Save money, improve safety and create a cleaner work environment.

Some of the ways that Ultra-Ever Dry can be used...

For industrial use only.

- Bricks

- Industrial electronics

- Engines

- Protection from acids/bases

- Tools & equipment

- Paint equipment

- Air stripper trays

- Nuts, bolts and other hardware

- Cement trucks & pumps

- Prevent buildup

- Building supplies

- Boats & marinas

- Machinery

- Electric motors

- Paper mill wet section equipment

- Cinder blocks

- Corrosion prevention

- Fall protection

- Cooling coils

- Condensers

- HVAC

- Work vehicles

- Waterproofing

Frequently Asked Questions

The bottom coat bonds to most materials and acts as a primer. It provides a consistent material for the top coat to bond to while interacting with the top coat to self-assemble the surface, creating finely textured geometry. This surface is comprised of patterns of geometric shapes and billions of interstitial spaces. There are “high points” in the surface that help to create a low surface energy, which causes droplets of water to touch a very small percentage of the coating. The water in the droplet that does not touch these “high points” is held together by intermolecular cohesive forces of the water molecules. It is the combination of these elements that allow Ultra-Ever Dry to be superhydrophobic and oleophobic for some, but not all, oil-based liquids.

Ultra-Ever Dry® surface protection coating creates a solid/liquid contact angle of 160-175 degrees in air. Well-known windshield water repellents have a contact angle closer to 110 degrees and are only hydrophobic. A superhydrophobic contact angle allows for the self-cleaning properties associated with Ultra-Ever Dry®. Oleophobicity refers to the ability to repel some, but not all, oil-based liquids (which have values of surface tension less than that of water). Unfortunately, oleophobicity is not an absolute term, as many oils have broad ranges of surface tension which may straddle the limit of the effective range of Ultra-Ever Dry®. For many oils, testing is required to determine if the specific oil or grade of oil will be repelled by Ultra-Ever Dry®.

The Ultra-Ever Dry® formula is susceptible to environmental conditions such as UV. This coating will offer approximately one year of outdoor life before recoating of the top coat would be required. When used in indoor or covered applications outdoors, the coating should last for a year or more. If the top coat has diminished due to environmental conditions, simply reapply the top coat to regain the superhydrophobic properties (assuming the bottom coat is still present). Ultra-Ever Dry® coating is also susceptible to abrasion.

The working temperature range for a coated surface is from -30°F to 300°F (-34°C to 149°C) once it has been applied. We would recommend further testing for any application that will be exposed to temperatures above 300 °F (149 °C). The coating should be applied at temperatures between 50°F to 90°F (10°C to 32°C).

Please note that the coating has a hazy translucent white appearance. Almost any material is a candidate for application: steel, aluminum, other metals, plastic, leather, fabric, wood, concrete, etc. The coating can be applied to and will bond to smooth surfaces. Preparing an already cleaned surface with heavy-duty scotch brite and/or sanding the surface with 320-800 grit sandpaper will improve adhesion. Ultra-Ever Dry® is not recommended for use on acrylics due to the high solvent content.

Ultra-Ever Dry® surface protection is significantly more abrasion resistant than previous superhydrophobic materials, registering a result of 30 cycles with a CS-10 wheel and 1000g load on the Taber Abraser before droplets no longer roll off the coating at a slope of 5 degrees from horizontal. The coating may still be superhydrophobic at this point, but droplets may “pin” or stick in the abraded area, and may not roll off until the substrate is tilted to a greater degree. If abrasion is a concern, testing is recommended. If the coating is removed due to repeated or severe abrasion, it can be reapplied.

Perhaps. In many situations, the superhydrophobic nature of the material may be diminished but the remaining top coat and bottom coat still provide the functionality of keeping the coated material from getting wet, iced up or corroding. This is application dependent.

The standard product is a hazy translucent white. We do not have a transparent formula at this time. Custom colors are not available at this time. It is recommended to try the coating in an inconspicuous area first if the color is important.

250 square feet or 23 square meters at a dry film thickness of 0.5 mils (13 microns).

Bottom Coat: Allow 30-60 minutes of dry time before applying top coat. A heat gun / blow dryer may be used on a low setting to decrease dry time.

Top Coat: The coating will become superhydrophobic within 15-30 minutes of the top coat application. Allow 2 hours of additional dry time for good results.

For best results, including optimum oleophobicity, allow the bottom coat to dry for at least 1 hour and allow the top coat to dry overnight.

Typically, the shelf life of the product will be four years when stored between 40°F and 115°F (4°C and 40°C).

Ultra-Ever Dry® coating is adversely affected by ultraviolet (UV) light, reducing its useful life. Additional Ultra-Ever Dry formulas are being developed to reduce the effect of UV light.

As with most materials and coatings, this will depend on the chemical. In general, it is resistant to a wide range including many water-based acids and bases. It may or may not be compatible with oil-based liquids, since these substances have varying values of surface tension, and liquids with low values of surface tension are not compatible with Ultra-Ever Dry®. Testing may be required to ensure proper compatibility. Ultra-Ever Dry® surface protection will not work with organic solvents including, but not limited to: acetone, xylene, t-butyl acetate, naphtha, MEK, etc.

Soaps and detergents will cause the surface of the coating to “wet-out”. Once these chemicals are removed (using low-pressure water), the superhydrophobicity will generally return. Alcohols and solvents will dissolve/remove the coating.

Strong acids and bases are typically not a problem. Testing has been completed with sulfuric, hydrochloric, and phosphoric acid with excellent results. We have also seen good results shedding strong caustic and some bleach solutions.

Ultra-Ever Dry

Part

Model

Color

Quantity

Average Coverage

Part

Model

Color

Qty

Average Coverage

4000

Bottom Coat

Translucent White

1 Quart

62.5 (6)

4001

Top Coat

Translucent White

1 Quart

62.5 (6)

4002

Bottom Coat

Translucent White

1 Gallon

250 (23)

4003

Top Coat

Translucent White

1 Gallon

250 (23)

4004

Bottom Coat

Translucent White

5 Gallons

1250 (116)

4005

Top Coat

Translucent White

5 Gallons

1250 (116)

4008

Bottom Coat

Translucent White

50 Gallons

12500 (1150)

4009

Top Coat

Translucent White

50 Gallons

12500 (1150)